Flow Pack Horizontal Packaging Machines

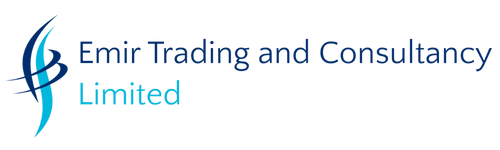

CARINA 500E

Horizontal Flow-Pack machine complete with rotary sealing jaws and Film Roll Holder from the top, composed of:

- Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

- Cantee-lever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

- 2100mm long infeed conveyor (usable loading space 1400mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

- Food grade nylon pushers and pushers supports;

- Longitudinal fin seal assembly carried out by 2 sets of independent fin wheels diameter 120mm. First set is for pulling , second one is for sealing;

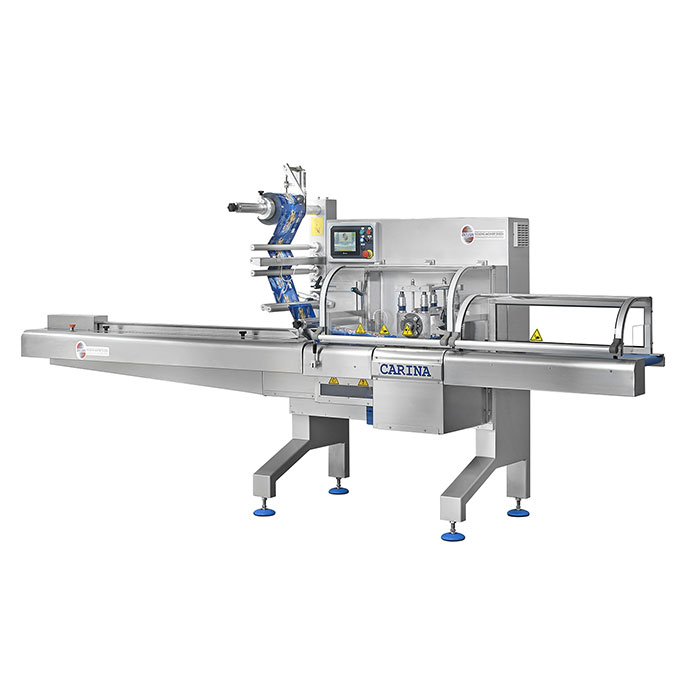

AURİGA 500 E

Horizontal Flow Wrapper Top Reel holder equipped with 3 servo motors.

Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

Cantilever machine execution with mechanical transmissions positioned behind machine separated and isolated from working surface and protected from dirt and product residues;

Integrated Electrical system and protected within the machine frame;

2100mm length infeed conveyor with removable plastic pushers (usable loading space 1400mm approx.) complete with stainless steel AISI 304 deck plates and side guards (upon request longer or shorter execution are available)

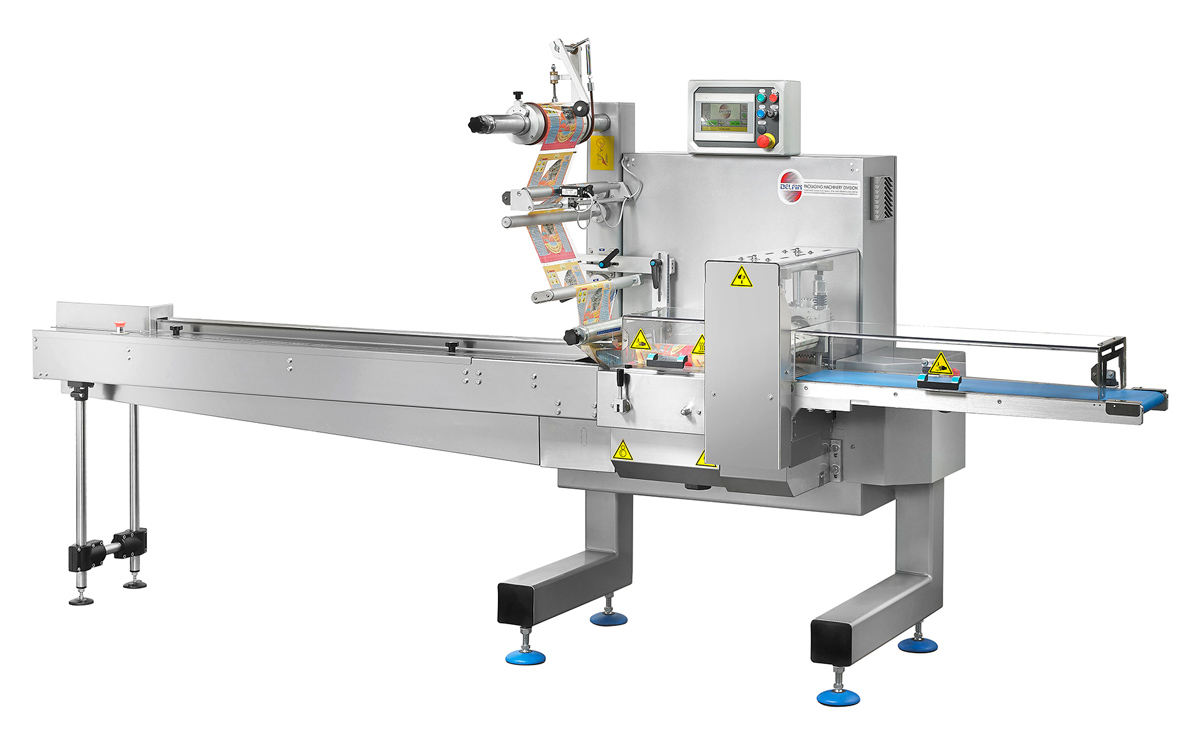

ORION 700 E

Electronic Horizontal Flow-Pack machine complete with rotary sealing jaws and Film Roll Holder from the top, composed of:

Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

Cantee lever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

2600mm long infeed conveyor (usable loading space 1800mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

Food grade nylon pushers and pushers supports;

Longitudinal fin seal assembly carried out by 3 sets of independent fin wheels diameter 120mm. First set is for pulling , second one is for sealing and third one is for driving. Pneumatic opening of the fin wheels;

One up-rotary motion sealing assembly with 350mm wide jaws and transverse or longitudinal sealing pattern complete with inclined cutting knife assembly . Sealing surface width 12,5mm.

GEMINI 500 E

Horizontal Flow-Pack machine complete with rotary sealing jaws and Film Roll Holder from the bottom, composed of:

Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

Cantilever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

2100mm long infeed conveyor (usable loading space 1700mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

Food grade nylon pushers and pushers supports;

Longitudinal fin seal assembly carried out by 2 sets of independent fin wheels diameter 120mm. First set is for pulling, second one is for sealing;

One up-rotary sealing assembly with 240mm wide jaws and inclined cutting knife assembly. Standard sealing width 12,5mm

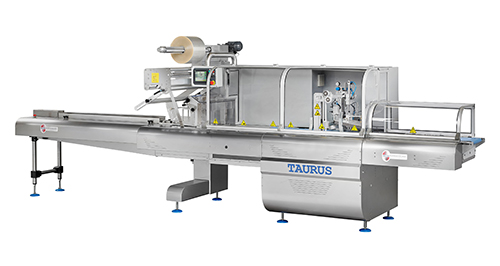

TAURUS 700 E

Electronic Horizontal Flow-Pack machine complete with box motion sealing jaws and Film Roll Holder from the top, composed of:

Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

Cantilever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

2600mm long infeed conveyor (usable loading space 1800mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

Food grade nylon pushers and pushers supports;

Longitudinal fin seal assembly carried out by 3 sets of independent fin wheels diameter 120mm. First set is for pulling , second one is for sealing and third one is for driving, pre-heating system and cooling devices. Automatic opening of the fin wheels.

GALAXY 700 E

Electronic horizontal flow-pack machine complete with box motion sealing jaws and film roll holder from the bottom, composed of:

- Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards ;

- Cantilever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

- 2600mm long infeed conveyor (usable loading space 2200mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

- Food grade nylon pushers and pushers supports;

- Longitudinal fin seal assembly carried out by 3 sets of independent fin wheels diameter 120mm. First set is for pulling , second one is for sealing and third one is for driving pre-heating system and cooling devices. Pneumatic opening of the fin wheels;

TUCANO 600 E

Horizontal Flow-Pack machine complete with box motion sealing jaws and Film Roll Holder from the bottom, composed of:

Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards , covers and 4 height adjustable feet;

Cantilever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

2600mm long infeed conveyor (usable loading space 1800mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

Food grade nylon pushers and pushers supports;

Longitudinal fin seal assembly carried out by 3 sets of independent fin wheels diameter 120mm. First set is for pulling, second one is for sealing and third one is for driving. Pre-heating system and cooling devices. Pneumatic opening of the fin wheels;

One box motion sealing assembly with 350mm wide jaws and pneumatic guilloting cutting knife assembly

Vertical Packaging Machines

COLORADO PP –PE Vertical Packaging Machine

Vertical form, fill and seal machine, model COLORADO PP/PE , controlled by PLC.

General technical characteristics:

Main Structure made of varnished steel;

Electrical cabinet is fixed to the machine;

Motorized film-reel unwinding system;

Motorized film-pulling unit;

Self-centering reel holding unit;

Sealing system with 3 independent movements, for a better sealing and for the prevention of the knife breakage;

Bag length measuring system: Encoder

End of film automatic detection system with automatic machine pause when the film-reel is over;

Sealing bar safety device;

Impulse Sealing System: with sealing band (PE) or Hot Bar (PP);

Air cooling system in the sealing area;

Interchangeable forming tube having. external diameter of max 170mm;

KANSAS 660 Vertical Packaging Machine

VERTICAL PACKAGING MACHINE MOD. KANSAS D 660 PE

Vertical packaging machine, for use of polyethylene material and controlled by Plc Delta.

General technical characteristics:

– Main structure made of RAL 7035 painted steel;

– Electric control panel incorporated on the machine;

– Motorized reel unwinding group;

– Motorized film feeding;

– Cut-and-sew with three independent movements, for a better quality of the welding and for the protection of the knife;

– Bag length measurement with encoder

– Fine-film control with automatic machine stop;

– Safety on the overlock;

– Welding system: flat impulse

– Interchangeable shaping tube;

– Max. Length single stroke packaging: 200 mm and 400 mm triple stroke;

– Max width. flat packaging: 300 mm;

– Max width. reel band: 660mm

– Outfeed tape Incorporated to the machine with motorized height adjustment

– Machine management via PLC Delta.

– Voltage: 400Vac-3Ph + N-50Hz

– Installed power: 3.5 Kw

– Compressed air: 6 Atm

– Total compliance with current CE standards.

YUKON PE-PP Vertical Packaging Machine for Single Fold Film

General technical features:

- Main structure made of RAL 9006 painted steel;

- Electric control panel incorporated on the machine;

- Pneumatic reel holder shaft;

- Film end detection device;

- Motorized film drive;

- Film pulling unit by means of Linatex coated toothed belts;

- N. 1 Product loading station protected according to the accident prevention regulations in force;

- Pneumatic welding and horizontal cutting unit, by means of a welding strip and knife.

FREEMONT Bagging Machine

General technical features:

- Main structure made of RAL 9006 painted steel;

- Electric control panel incorporated on the machine;

- Pneumatic reel holder shaft;

- Film end detection device;

- Motorized film drive;

- Film pulling unit by means of Linatex coated toothed belts;

- N. 1 Product loading station protected according to the accident prevention regulations in force;

- Pneumatic welding and horizontal cutting unit, by means of a welding strip and knife.

Stand Up Pouch Packaging Machine

BRAVO 150 Automatic Traysealing Machine

The best solution for the packaging of preformed trays.

Automatic machine, very compact, realized on stainless steel and anodized aluminum and with high quality material and components.

Knee lever system for the bottom chamber movement to guarantee an excellent welding on all packaging types and then an optimal sealing.

It is distinguished by the easy and quick way to change the mould, less than five minutes.

It’s very versatile, it can be equipped with customized dosing systems, de-nesters, photocells for print registration, etc.

BRAVO 150 allows the SKIN-PACK packaging!

Stand Up Pouch Packaging Machine

PECOS Vertical Packaging Machine For Stand Up Pouch

Vertical packaging machine mod. PECOS controlled by Siemens Plc for Stand Up Pouch.

General technical features:

Main structure made of RAL 9006 painted steel;

Electric control panel incorporated on the machine;

Motorized Self-Centering Film Folding Device;

Film end detection device;

Bellows forming device on the bottom;

Motorized film drive;

Film pulling group by means of toothed belts covered in Linatex motorized with Brushless;

Vacuum Packaging Machines

VALKO LINE 08/210

Countertop vacuum chamber packaging machine. Removable sealing bar without cables for an easy and fast cleaning. Ideal for small locations or domestic use.

- Compact machine

- Suitable for small places or for domestic use

- Digital, stainless steel made, set of volume reducers included

- Electronic board with sealing time regulation

- Sealing bar without cables for an easy and fast cleaning

- Easy to clean chamberEasy to clean chamber

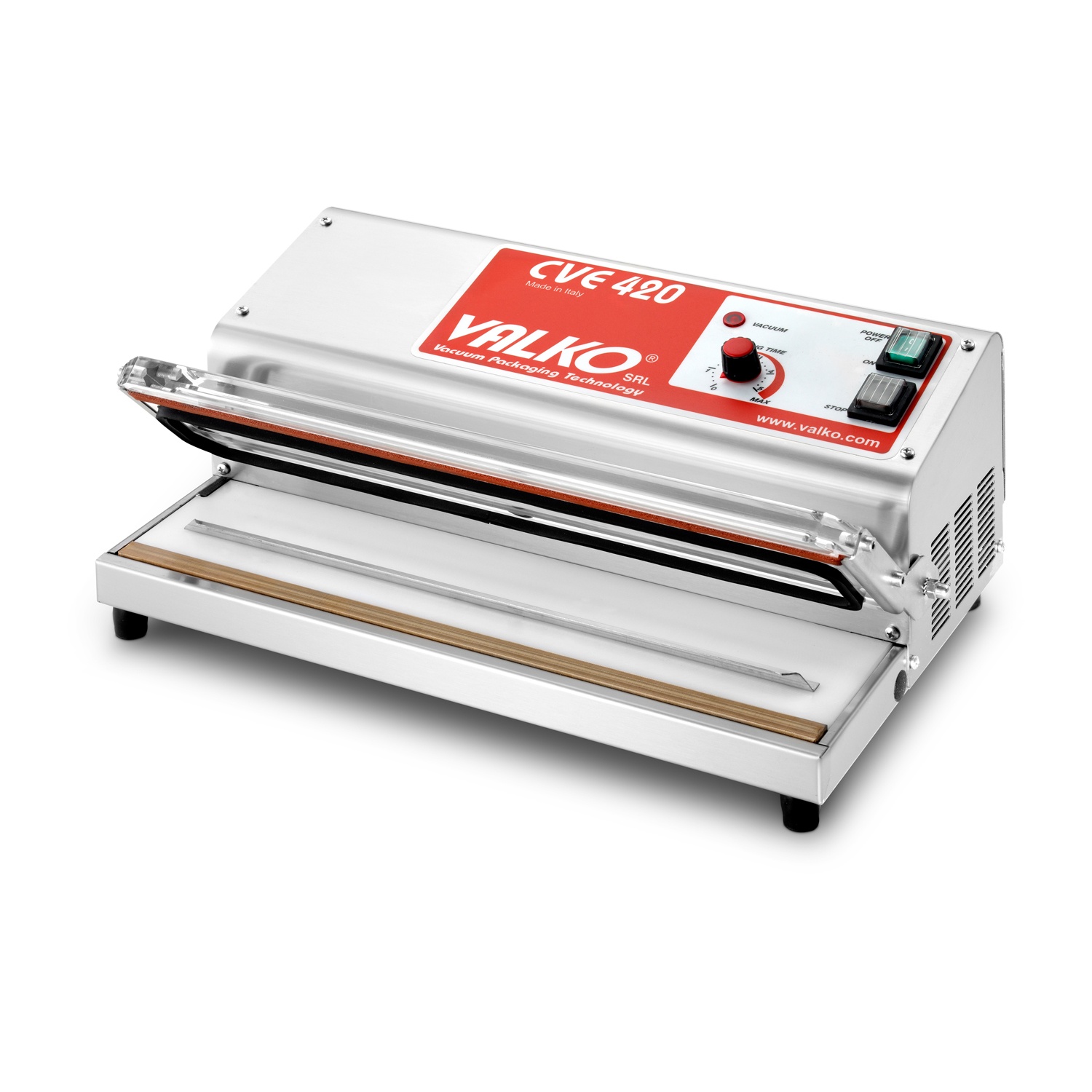

DRY PUMP –EXTERNAL VACUUM PACKAGİNG MACHINES

Stainless steel external vacuum packaging machine with 420 mm long sealing bar and dry vacuum pump. It operates only with embossed or gusset bags.

- Suitable for small bars

- It works with embossed or gusset bags

- Vacuum in trays by using a specific probe

- Suitable for bags up to 420 mm width

Chamber Vacuum Packaging Machine

Vacuum preservation is the best guarantee to maintain the quality of raw food which still needs to be processed, and of already cooked food. Durability and freshness of the product are ensured by the almost total absence of oxygen, achieving a 99% maximum vacuuming. In fact, even if it is the wrapping which protects the product from external agents and odors, it is the percentage of vacuum inside the bag that extremely slows down the proliferation of bacteria that causes its deterioration.

- 315mm long sealing bar

- Chamber size – 322w x 365d x 160hmm

- Dims; 392w x 510d x 345h

- Electric; 0.9kw – 4amp

Table Top Chamber acuum Packaging

Counter-top vacuum chamber packaging machine. Removable sealing bar without cables. Sealing bar 315mm. Suitable for smaller places or bars.

- Bestseller line

- Suitable for small restaurants and delis

- Digital, stainless steel made, set of volume reducers included

- Electronic board with vacuum control

- Vacuum in Gastronorm trays by using a specific probe

- Sealing bar without cables for an easy and fast cleaning

Table Top Chamber Vacuum Packaging

Vacuum preservation is the best guarantee to maintain the quality of raw food which still needs to be processed, and of already cooked food.

- Chamber size: 390x285x55mm

- SS304 stainless steel chamber

- Seal bar (length & width): 260x10mm (single)

- Vacuum-pump efficiency: 8m³/h

- Voltage: 220V / 1 Phase / 50Hz

- Pump power: 320W

- Pump motor power: 180W

- Net weight: 31.6kg

- Dimensions: 510x350x390mm

FAVOLA 214-V

Countertop vacuum chamber packaging machine. Removable 210 mm sealing bar, without cables for an easy and fast cleaning . Compact machine, ideal for smaller locations.

- Compact machine

- Suitable for small places

- Digital, stainless steel made, set of volume reducers included

- Electronic board with vacuum control

- Sealing bar without cables for an easy and fast cleaning

- Easy to clean chamber

FAVOLA 415/6

Countertop vacuum chamber packaging machine with removable 500 mm sealing bar for an easy and fast cleaning. Possibility of packaging Gastronorm GN 1/2 trays. Ideal for large-scale retail chains and professional catering.

- Suitable for small butcheries, large-scale distributions

- Table-top vacuum machine with sealing bar of 500 mm

- Digital, stainless steel made, set of volume reducers included

- Electrical board with vacuum control

- Sealing bar without cables for an easy and fast cleaning

- Vacuum in GN ½ Gastronorm trays directly into the chamber

FAVOLA 500/25

Vacuum chamber packaging machine on wheels with removable sealing bar (500 mm), without cables for an easy and fast cleaning. Ideal for large-scale retail chains and medium-size butcher shops.

- Suitable for medium size butcheries, large-scale distribution

- Maximum bag dimension 500×500 mm

- Digital, stainless steel made, set of volume reducers included

- Sealing bar without cables for an easy and fast cleaning

- Easy to move thanks to the 4 pivoting wheels

- Electronic board with vacuum control

Chamber Vacuum Packaging Machines on Wheel

FAVOLA 560 RAPIDA

Vacuum chamber packaging machine on wheels with double sealing bar (2 x 500 mm), sealing wire and waste trimming. Ideal for medium-size butcher shops and large-scale retail chains.

- Suitable for butcheries, large-scale distribution, labs

- Maximum bag dimension 500×550 mm

- Digital, stainless steel made, set of volume reducers included

- Soft-Air included

- Wide chamber

- Easy to move thanks to the 4 pivoting wheels

- Electronic board with vacuum control

FAVOLA 560 SL

Vacuum chamber packaging machine on wheels with sealing bar (500 mm). Sealing wire and waste trimming. Equipped with printer for adhesive labels on which to report all the necessary information.

- Suitable for Batcheries, large-scale distribution, labs

- Digitale, in stainless steel, set of volume reducers included

- Control panel with PLC

- Full optional machine with MAP, Soft-Air and lid fastener

- Equipped with printer for adhesive labels where ingredients, operator, batch, packing and expiry dates can be displayed

- Suitable for places with many operators

FAVOLA 500 TWIN 100 SL

Vacuum chamber packaging machine on wheels., sealing bar with sealing wire and waste trimming. Equipped with printer for adhesive labels on which to report all the necessary information. Ideal for large butcher shops, large-scale retail chains and labs.

- Suitable for labs, large-scale distributors

- Double chamber with 1 sealing bar 500 mm for each chamber

- Alternate and Continuous rapid cycle

- Digital, stainless steel made, set of volume reducers included

- Suitable for those who need to optimise the packing time

- It allows the packaging of one or more bags at once by using one chamber, whilst positioning the products in the other one

- Equipped with printer for adhesive labels where ingredients, operator, batch, packing and expiry dates can be displayed

- Full optional machine with MAP, Soft-Air and lid fastener

- Suitable for places with many operators

Hermetic Tray Sealers

SG400-18

Hermetic manual tray sealer with quick mold changing system. Universal sealing plate. Tray profile cutting available upon request. Ideal for gourmet food stores and central kitchens.

- In stainless steel, suitable for gastronomies, central kitchens

- Suitable for different tray sizes

- Automatic winding of the film while pushing the mould in

- Adjustable buzzer from 0 to 10 secs to signal the end of the cycle

- Inclusive universal sealing plate

- Profile cut moulds available

Tray Sealers For Skin Pack

Vacuum pack tray sealer. Skin-Pack vacuum packaging. Customizable mold. Suitable for 100 mm tray. Up to 2 cycles per minute.

- In stainless steel, on wheels, with no. 3 volume reducers included

- Skin Vacuum packaging

- Customizable moulds

- Suitable for trays with a maximum height of 100 mm

- Control Panel with 5 pre-set programs

- Up to 2 cycles per minute

E-SG 420

Semiautomatic tray sealer. Customized mold and automatic sealing cycle. With universal sealing plate, without molds.

- In stainless steel, suitable for gastronomies

- Compressed air not requested

- Automatic winding of the film while pushing the mould in

- Automatic sealing cycle

- Adjustable sealing time from 0 to 10 secs

- Quick and easy sealing plate changing

P-SG 420 CF

Semiautomatic tray sealer. Automatic sealing cycle. Complete with customized mold with profile cut. Ideal for ready meals and fresh, ready to be consumed vegetables (Gas Flushing).

- In stainless steel, suitable for gastronomies

- Ideal for ready meals and fresh cut products

- Compressed air needed

- Automatic winding of the film while pushing the mould in

- Automatic sealing cycle

- Adjustable sealing time from 0 to 10 secs

Map Tray Sealers

Micra 8

Vacuum tray sealer in MAP (Modified Atmosphere Packaging). Customized mold, universal sealing plate with 2 volume reducers included.

- In stainless steel

- Vacuum packaging with MAP option, 2 cycles per minute

- Customizable moulds

- Suitable for trays with a maximum depth of 85 mm

- Control Panel with 5 pre-set programs

- With automatic start

- Inclusive universal sealing plate and with no. 2 volume reducers included

Unica 25

Vacuum pack tray sealer on wheels. Packaging in MAP (Modified Atmosphere Packaging). Quick mold changing system. Suitable for up to 115 mm deep trays.

- In stainless steel, on wheels, with automatic start

- Vacuum packaging with MAP option

- Quick mould changing, customizable moulds

- Suitable for trays with a maximum height of 115 mm

- Control Panel with 5 pre-set programs

- Up to 1,5 cycles per minute

- With no. 3 volume reducers included, equipped with gas tank

Unica 20 SKIN

Vacuum pack tray sealer. Skin-Pack vacuum packaging. Customizable mold. Suitable for 100 mm tray. Up to 2 cycles per minute.

- In stainless steel, on wheels, with no. 3 volume reducers included

- Skin Vacuum packaging

- Customizable moulds

- Suitable for trays with a maximum height of 100 mm

- Control Panel with 5 pre-set programs

- Up to 2 cycles per minute

TVG MAXI 60 H35

Vacuum pack tray sealer. MAP and Skin-Pack vacuum packaging (maximum sealing height 35mm). Large trays packaging. Designed for supermarkets, catering and gastronomy. 60 m³/h vacuum pump.

ADVANTAGES:

- Suitable for butcheries, pasta factories, large scale distributions and laboratories

- Type of packaging: MAP (modified atmosphere packaging) and SkinPack on cardboard and tray

- Up to 3 cycles per minute

- Suitable for trays with a maximum height of 115 mm

- Maximal overskin* height 35 mm

- In stainless steel and on wheels

*Protrusion of the product from the cardboard or above the edge of the tray

TVG MAXI 60 MAP

Vacuum pack tray sealer. MAP vacuum packaging. Large trays packaging. Designed for supermarkets, catering and gastronomy. 60 m³/h vacuum pump.

ADVANTAGES:

- Suitable for butcheries, pasta factories, large scale distributions and laboratories

- Type of packaging: MAP (modified atmosphere packaging)

- Up to 3 cycles per minute

- Suitable for trays with a maximum height of 115 mm

- In stainless steel and on wheels

INCLUDED:

- Quick mould changing

- 1 customized mould with profile cut (MAP)

- Automatic film waste collection

- Control Panel with 5 pre-set programs

- No. 3 volume reducers

Map And Skin Pack Packaging Lines

LINEA 470

Automatic tray sealer. Vacuum chamber. Single, double or triple impression mold. Operator touch-screen panel. Max impression 400 x 285 mm. 100 m³/h vacuum pump.

ADVANTAGES:

- Suitable for butcheries, pasta factories, large scale distributions and laboratories

- Type of packaging: MAP (modified atmosphere packaging) and SkinPack on cardboard and tray

- Up to 5 cycles per minute

- Suitable for trays with a maximum height of 100 mm

- Maximal overskin* height 10 mm

- Automatic cycle start

- In stainless steel

- Moulds and vacuum chamber made by aluminium Peraluman

*Protrusion of the product from the cardboard or above the edge of the tray

Do you have any question about our services?

We provide free consultation so lets talk with us!