Biscuit and Cookie Depositing Machine

BISCUIT DEPOSITING MACHINE MOD. MINO 400-B

- Bench machine (optional, stainless steels trolley with 4 castors)

- Main frame is constructed in anti corodal aluminium and stainless steel Aisi 304

- Tray transport conveyor 1mt

- Standard rollers extruding head for semi-dense dough

- Fixed nozzle plate with 6 exits complete of n.2 standards nozzles kits

- Rotary nozzle plate assembly (Optional) complete of n.2 standard nozzles kits

- Pump head for semi-liquid dough (Optional)

- Computer with new Graphic display “Touch Screen”, intuitive control panel

- EC standards

- Machine suitable for trays 40 x 60 x H-2 cm, manual loading

- instruction manual

- reduced machine dimensions, considering modular structure

Weight: indicative 170/200 Kg (gross 250kgs – to be confirmed at order)

BISKY 400-B

a) Cantee lever machine with 4 castors

b) Main frame is constructed in anti corodal aluminium and stainless steel Aisi 304

c) Tray transport conveyor

d) Standard rollers extruding head for semi-dense dough

f) Fixed nozzle plate with 6 exits complete of n.2 standards nozzles kits

g) Rotary nozzle plate assembly (Optional) complete of n.2 standard nozzles kits

h) Pump head for semi-liquid dough (Optional)

i) Computer with Graphic display “Touch Screen”, intuitive control panel

j) EC standards

k) Machine suitable for trays 40 x 60 x H-2 cm, manual loading

alternative models as Bisky 460 (46×66) or Bisky 600 (600×800)

l) instruction manual

g) strong modular structure, indicative weight 350Kg+

JUCAR 600 JAM

DUERO 400-B

DUERO 400-B

with graphic automatic control panel.

Scope of the supply :

Biscuit depositing machine to produce a complete variety of shapes within the limits and according to the standard kit of nozzles.

Functional and constructive characteristics

a) Cantee lever machine with 4 castors

b) Main frame is constructed in anti corodal aluminium and stainless steel Aisi 304

c) Tray transport conveyor

d) Standard rollers extruding head for semi-dense dough

e) n.3 brushless motors (extruding rollers, table movements, belt movement)

f) Fixed nozzle plate with 6 exits complete of n.2 standards nozzles kits

TOGO 600

Machine main characteristics

Cantee lever style construction machine, to ensure precision and robustness.

Main frame is constructed in anti corodal aluminium and stainless steel Aisi 304

n.4 brushless motors (extrusion rollers, table lifting, belts movements) in order to achieve fast and precise movements, low maintenance and extreme reliability.

Tray transport converyor, machine suitable for trays 60 x 80 x 2 cm, manual loading.

Easy dismantling of the hoppers and rollers head in order to carry out daily cleaning operations (Optional trolley on wheels with height adjustment for the removal of the roller chamber)

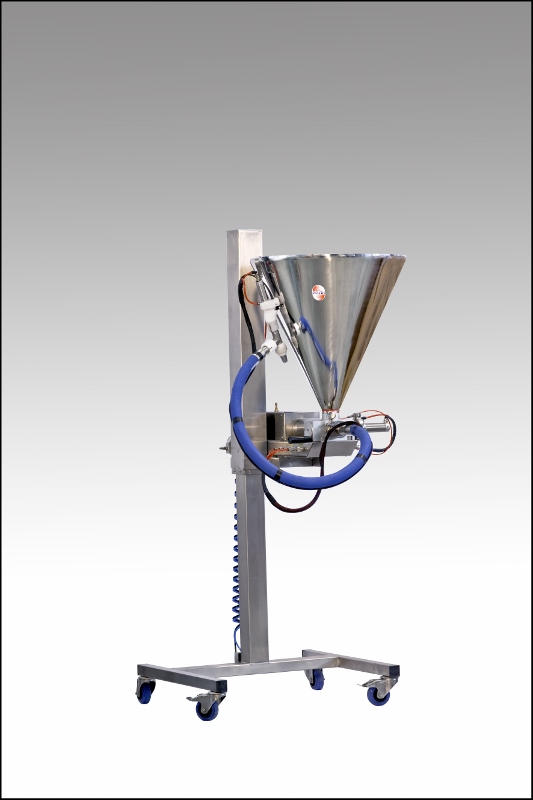

Pneumatic Depositor & Pastry Filling Machines

Pneumatic Depositor

Functional and constructive characteristics.

- Main frame is constructed in stainless steel Aisi 304, assembled on 4 castors.

- Hopper constructed in stainless steel Aisi 304, capacity 46 Lt. (Hopper can be dismantled without the use of spanners).

- Automatic lifting/lowering of the depositor by means of a

lever. (pneumatic lifting/lowering system) - One Dough cylinder is included in the machine price, sizes available :

o 10-63 ml – suitable for the muffins, included in basic machine price. - 20-129 ml

- 41-253 ml

- 64-395 ml

- 92-570 m.

Mini- Fill-Electric

Series

- Mini-fill Electric 100 W

- Mini-fill Electric 260 W

Design Features

- compact electric filling machine for depositing, injection, layering and decoration

- easy-to-use colour touch screen

- you can store up to 100 recipes in the menu with

Mini-Fill-Electric-Pneumatic

- compact electric filling machine for depositing, injection, layering and decoration

- easy-to-use colour touch screen

- you can store up to 100 recipes in the menu with their corresponding dosing settings

- applications:

- depositing of muffins, fruit fillings, jams and jellies, creams;

- injection of éclairs, Berliners, profiteroles;

BELTOP UNO DEPOSITOR

Series

- Beltop 275 UNO Depositor

- Beltop 670 UNO Depositor

Design Features

- compact versatile volumetric stainless steel depositor for benchtop use

- mounted on a compact non-adjustable frame

- applications:

– depositing of cake batter, muffins, jam, jelly, fruit filling, cream, mousse, meringue, ice-cream, yoghurt, soup, sauce, mashed potatoes, minced meat, salad;

– injection of éclairs, Berliners, profiteroles;

– decoration;

Beltop Depositor /Filling Machine

- Beltop 275 Depositor

- Beltop 670 Depositor

Design Features

- compact versatile volumetric stainless steel depositor for benchtop use

- mounted on height adjustable feet

applications:

- depositing of cake batter, muffins, jam, jelly, fruit filling, cream, mousse, meringue, ice-cream, yoghurt, soup, sauce, mashed potatoes, minced meat, salad;

- injection of éclairs, Berliners, profiteroles;

Belcake Advanced Depositor

- Belcake 670 Advanced Depositor

- Belcake 1340 Advanced Depositor

Design Features

- volumetric stainless steel depositor, specially designed for cake production

- applications: depositing of cake batters, icing of middle layers, top/side finishing of cakes, decoration

Cake Lines

Beldos cake line is a modular system for semi-automatic cake production. This means that all machines function autonomously, that the line can be fitted with additional devices at any time and grow step by step – depending on your budget and production needs.

Applications

- slicing of sponge

- syrup spraying

- icing of mid layers and top+side icing

- decoration

Do you have any question about our services?

We provide free consultation so lets talk with us!